OEM TRAINED. REAL-WORLD EXPERIENCE.

HOW CAN WE HELP YOU?

COMPREHENSIVE AUDITS

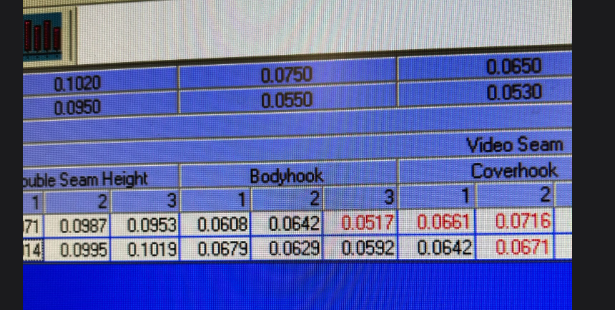

Performing a thorough audit of your beverage can seamer can identify potential issues or preventative maintenance opportunities long before they turn into emergency break/fix situations. A comprehensive audit performed by The Fresh Grease Maintenance Company will provide you with a multi-point inspection report accompanied by the necessary OEM-specific part numbers for any required spare parts order. Audit reports always contain explanations with pictures for context to ensure clear understanding of the recommendations.

PREVENTATIVE MAINTENANCE

Regular maintenance of your beverage can seamer is critical in order to avoid costly, unplanned downtime and potential equipment damage. The Fresh Grease Maintenance Company can recommend and perform preventative maintenance service on your machine in a timely and cost-effective manner. The recommended maintenance intervals are:

- 1000 hours (annual)

- 5000 hours

- 10,000 hours

Of course, every customer and every machine is different, so often the best path to performing the proper preventative maintenance is to schedule a comprehensive audit.

EMERGENCY BREAK/FIX

In the event of a breakdown, there are two important metrics: the time it takes to make a correct diagnosis of the issue, and the time it takes to complete the repairs. Therefore it is imperative to work with experts who can provide effective triage and return your equipment to service as quickly as possible. A few ways The Fresh Grease Maintenance Company sets itself apart from other providers:

- Service Availability

- 24/7 support for MMS customers

- 24-48hrs on-site support for general emergency services

- Technical Capability

- Specifically trained on various brands of beverage can seamers

- Vast knowledge base of issue resolutions

- Triage & Repair

- “Outside the box” temporary repair solutions

- Alternative spare parts sourcing

The best methods to safeguard against unplanned downtime are to plan regular maintenance, provide updated operator training, and keep critical spare parts on-site.

OPERATOR TRAINING

The Fresh Grease Maintenance Company can equip your canning line operators with basic and advanced skills to keep things running smoothly and maintain OEE standards. Training is performed at your facility with learning sessions tailored to your specific machine setup.

A great way to make operator training even more effective is to tie it in with a preventative maintenance service.

REMOTE SUPPORT

When you have questions and need to talk to an expert, The Fresh Grease Maintenance Company is a phone call or email away. Contact us for information and pricing on annual support plans.

CONSULTING

Whether you need advice on acquiring used canning line equipment, or are considering adding new can formats to your existing system, The Fresh Grease Maintenance Company will provide expert consultation backed by real-world experience.